All About Spandrel Glazing

Table of ContentsOur Spandrel Glazing DiariesGetting My Spandrel Glazing To Work

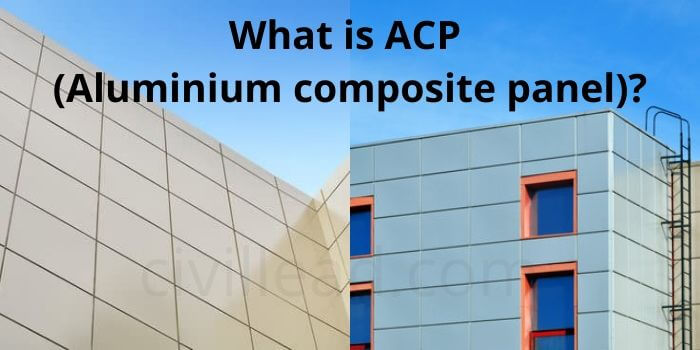

Construction site panel made from aluminium composite product (Dibond) Information view of building and construction website panel Aluminium composite panels (ACP), made from aluminium composite material (ACM), are flat panels containing 2 thin coil-coated aluminium sheets bonded to a non-aluminium core. ACPs are frequently made use of for outside cladding or facades of buildings, insulation, and also signage. ACP is mostly utilized for outside and internal building cladding or partitions, false ceilings, signs, device treatments, container construction, etc. Applications of ACP are not restricted to exterior building cladding, however can additionally be utilized in any kind of form of cladding such as dividers, incorrect ceilings, etc.

ACP has actually been made use of as a light-weight but very strong product in building and construction, specifically for transient structures like trade convention booths and similar short-lived elements. It has recently likewise been taken on as a backing material for placing art digital photography, usually with an acrylic coating making use of processes like Diasec or various other face-mounting methods. ACP product has been used in famous structures as Spaceship Planet, Van, Dusen Botanical Garden, the Leipzig branch of the German National Collection. These structures made optimum use of ACP via its cost, toughness, as well as effectiveness. Its versatility, low weight, and also very easy developing as well as processing permit innovative layout with boosted rigidness and resilience (spandrel glazing).

The basic ACP core is polyethylene (PE) or polyurethane (PU). These materials do not have excellent fireproof (FR) properties unless particularly dealt with and are therefore not usually appropriate as a building product for houses; a number of jurisdictions have outlawed their usage completely. Arconic, proprietor of the Reynobond brand name, cautions the possible purchaser. Concerning the core, it claims that range of the panel from the ground is a determinant of "which products are much safer to use". In a sales brochure it has a graphic of a structure in flames, with the caption" [a] s quickly as the building is more than the firemans' ladders, it has to be developed with a fireproof material".

70% mineral core) from there to as much as c. 30 meters, the elevation of the ladder; and the European A2-rated product (c. 90% mineral core) for anything above that (spandrel glazing). In this sales brochure, Fire Security in Skyscraper: Our Fire Solutions, item requirements is only provided for the last two items. The cladding products, specifically the core, have actually been linked as a possible contributing element in the click here to find out more 2017 Grenfell Tower fire in London, in addition to in skyscraper fires in Melbourne, Australia; France; the United Arab Emirates; South Korea; and the United States. Fire-rated cores, such as mineral wool (MW), are an alternative, however are normally extra pricey and typically not a legal demand.

Getting The Spandrel Glazing To Work

Aluminium can be painted in any sort of colour, and also ACPs are generated in a wide variety of metallic and non-metallic colours as well as patterns that imitate various other products, such as wood or marble. The core is generally low-density polyethylene (PE), or a mix of low-density polyethylene and also mineral product to exhibit fire resistant residential or commercial properties. 3A Compounds (formerly Alcan Composites view website & Alusuisse) designed aluminium composites in 1964 - as a joint development with BASF- and commercial production of Alucobond commenced in 1969. The item was patented in 1971, a license which expired in 1991. After the expiry of the license several firms started industrial production such as Reynobond (1991 ), Alpolic (Mitsubishi Chemicals, 1995), etalbond (1995 ).

05 W/( m, K) for mineral wool. Therefore, they can achieve different U-values relying on the core and also the density of the panel. The installment of a system with sandwich panels lessens thermal bridges with the joints. The examined sound reduction measurement lies at approx. 25 d, B for PU components and also at approx. 30 d, B for MW components. The room in between the assistances can be as much as 11 m (wall surfaces), relying on the type of panel used. Regular applications have rooms in between the assistances that are approx. 3 m 5 m. The density of panels is from 40 mm approximately even more than 200 mm.